Our mica nozzle heater bands are engineered for precise, consistent heat distribution in demanding applications such as injection moulding, extrusion tooling, hot runner systems, and packaging machinery. For high-temperature polymers and intensive production cycles, we also offer high-density nozzle heaters capable of continuous operation at up to 600°C. These units deliver exceptional thermal conductivity, durability, and process stability under extreme conditions.

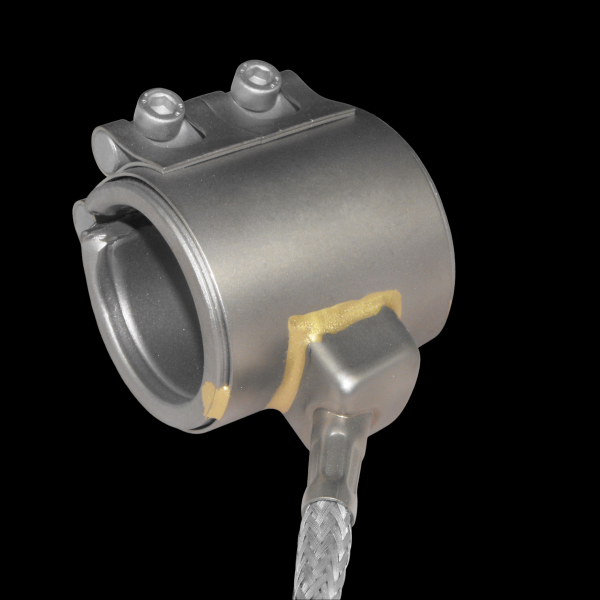

Each heater is fully customisable to suit your machine’s unique specifications. Standard design options include glass fibre or metal braided lead terminations, integrated thermocouples (Type J or K), dedicated earth leads, and flexible cable lengths. To ensure seamless integration, our heaters can also be manufactured with roller bolt clamps, sensor holes, threaded bridges, and shaped cut-outs as required.

All units are typically supplied in single-phase, with two-phase configurations available on request. Manufactured in the UK with short lead times and full technical support, our nozzle heaters offer reliable performance and long service life in a wide range of plastic processing environments.